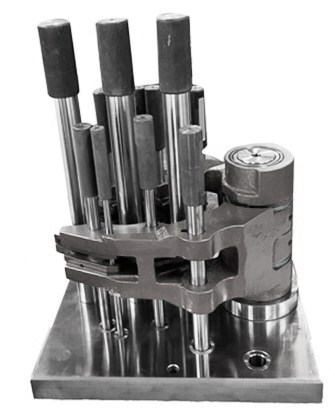

INSPECTION FIXTURES

Features & Benefits

- Enhanced Productivity: Eliminate defects and improve productivity by regularly checking Mould & Neck Ring equipment. Highly cost-effective solution.

- Inspection Fixtures: Includes Mould Holder and Inserts Inspection Fixtures for early identification of problems.

- Defect Elimination: Addresses defects such as heavy seams or cross joints.

- Comprehensive Checks: Inspects insert wear, bore diameter, misalignment, and Mould arm height.

- Neck Ring Arm Inspection: Checks for bore wear, groove width distortion, foot flatness, and center error.

- User-Friendly & Cost-Effective: Simple to use and very cost-effective.

- Precision Inspection: Baffle Arm, Blow Head Arm, and Funnel Arm inspection fixtures check main coordinate hole positions and alignment for trouble-free performance on the I.S. Machine.

- Plunger Alignment: Includes plunger alignment fixtures for precise adjustments.

- Custom Design: Capable of designing and developing any type of inspection fixture as per customer specifications for any type of I.S. Machine.